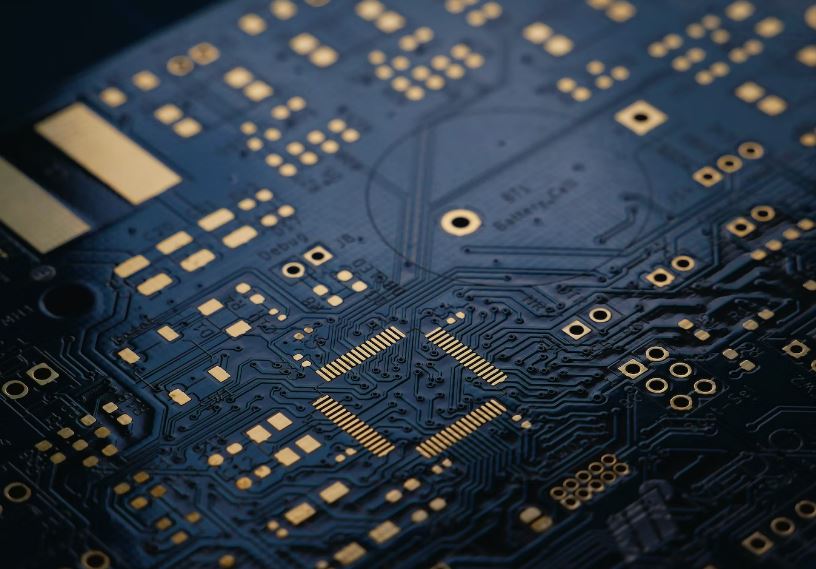

Printed circuit boards are a common component of electronic equipment. It is unsurprising given what they are capable of. But why are printed circuit boards used so frequently, and for what purposes? Let us go through the blog and find out!

What is a Printed Circuit Board, or PCB?

The bare board for which you provide the schematic data and which, after it is given to you, you use to place your components is known in the industry as a PCB or printed circuit board. Using electrical paths, tracks, or transmission traces chiseled from copper sheets coated onto a non-conductive surface, a printed circuit board is employed to mechanically sustain and electronically link electronic components.

Although more precise and distinguishable from what would be recognized as a genuine printed circuit board, the term “printed wiring board” (PWB) has generally lost favor with many people as the line between circuit and wire has gotten hazier. Currently, the finest commercially made electronic devices employ printed wiring (circuit) boards, which enable completely automated assembly procedures that were not feasible or viable in older tag-type circuit assembly techniques.

One of the least expensive solutions for mass production is printed circuit boards. Due to this, businesses that produce nothing else can survive. All kinds of circuit boards play a crucial role in the electronics sector. Printed circuit boards are the easiest to manufacture, which contributes to their increasing demand. There are many PCB manufacturing companies out there.

What Are Printed Circuit Boards Used For?

Printed circuit boards are used in more sectors and businesses than might initially appear. These tiny boards can be found in large industrial gear as well as small consumer electronics. To give you a general notion of how essential PCBs are to almost everyone, we would like to list some of their most popular uses.

-

Equipment for Security & Protection

Security systems frequently rely on the utilization of PCBs and SMT technologies, whether they are utilized for residences, governmental structures, or commercial buildings. Notwithstanding what many people are aware of, they have a significant impact on safety and security. Depending on the specific application, the PCBs used for these goods can vary, but all must be dependable since they must always function properly. Some security systems require an outdoor environment to function; therefore, they must be able to survive that as well. Modern electronic door locks, security cameras, and even smoke detectors all make use of PCBs.

-

Medical Equipment

The healthcare industry is continually incorporating new technologies, and PCBs give devices more possibilities. In devices for diagnosis, therapy, monitoring, and other purposes, printed circuit boards are employed. Since they are employed to enhance patient health, these PCBs must be incredibly dependable. They frequently have to adhere to strict sanitary requirements and function best when very small. Medical imaging techniques, injectables, sensors, and even supporting equipment are a few examples of medical equipment that uses PCBs.

-

LEDs

Both business and residential spaces frequently use LEDs, or light-emitting diodes, for lighting. Additionally, LEDs are employed in a variety of fields, including computer technology, transportation, and healthcare. The longevity, energy efficiency, and small size of LEDs are their main advantages. Since they can aid in heat transport away from the light source, PCBs are excellent for LEDs. Aluminum is frequently used in PCBs for LEDs to provide optimum performance because high temperatures cause LEDs to burn out more quickly. This makes it unnecessary to use a second heat sink and enables small, streamlined structures.

-

Components for Aerospace

The PCBs used in aerospace must be able to withstand extremely abrasive environments. These printed circuit boards might be found in a variety of devices, including satellites, spacecraft, and communication systems in addition to aircraft. Extreme temperatures and high levels of vibration are two challenging circumstances that the materials used to make these PCBs must tolerate. Some are considerably more resilient because they were designed for usage in space. In some circumstances, lightweight PCBs constructed of materials like aluminum can be helpful.

-

Electronic Products for Customers

PCBs with SMT technology is required for the functioning of a wide range of everyday gadgets, including computers, tablets, smartphones, and others. PCBs exist to guarantee the operation of the increasing number of electronics that are a part of everyone’s daily lives. The boards while still offering a wide range of capabilities support smaller laptops and other devices. To maintain low product pricing, the majority of consumer electronics PCBs are quite cheap. To keep customers happy, though, the boards also need to be dependable.

-

Computers

A PCB may perform more complex tasks than merely basic ones. The PCB can carry out any number of operations by incorporating particular components and using bespoke design. The PCB, often known as the motherboard in computers, is an excellent illustration of this.

-

Industrial Equipment

Printed circuit boards and SMT technology are widely used in the industrial world. In production and distribution facilities as well as other types of industrial operations, electronic components are employed to power a large portion of the equipment. Since PCBs in industrial settings may be exposed to extreme temperatures, rough handling, harsh chemicals, or vibrating machinery, they must be especially strong and robust to handle tough situations. They are frequently thicker than standard PCBs and are composed of strong metals that can withstand heat.

The Bottom Line:

Knowing the parts that make up printed circuit boards and how they are made is part of understanding them. Printed circuit boards come in three different categories. Choosing one is based on the requirements of the specific gadget. All relevant parts are located on a single side of single-sided boards. Parts are placed on both sides of double-sided boards. Multiple circuit layers are used to distribute the elements on multi-component boards. Insulation surrounds each one to keep it safe.

PCBs are so widespread for two reasons. First, the PCB is one of the most effective and intricate components that give a device a ton of capability. The ease of use of PCBs is another factor in their widespread use. Once a design is created, it is feasible to automate the creation of a PCB. Printed circuit boards are utilized for this in most cases now. Ultimately, the precise function of each PCB is ultimately determined by its distinct design.

John Mostly mostly writes about Energy and resources. He spends his time to research power banks, solar chargers & mobile phones. Apart from gadget enthusiast, he also loves camping & hiking with friends.